Corroplast

Around 335 million tons of plastic were produced worldwide alone in 2016 and the volume increases up to 348 million tons in 2017. Customers for the robust and easy-care material are principally of the packaging industry, suppliers to the automotive, electrical and medical industries, building and construction industry.

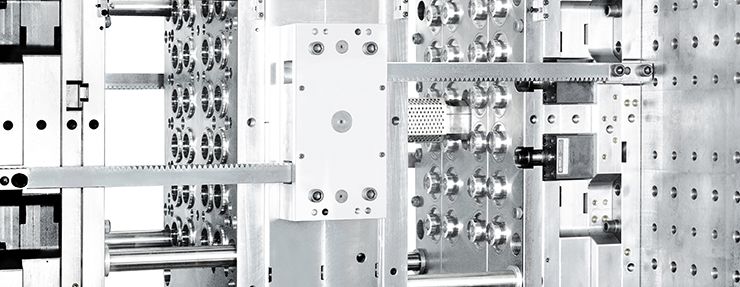

Corroplast for most demanding corrosion resistant plastic molds

Corroplast is a pre-hardened free machining stainless steel mold base material. Corroplast is the ideal material to resist corrosion associated with high humidity environments and when corrosive resins are used in the production. In addition, Corroplast is the preferred mold base material for medical and food packaging applications.

Advantages of Corroplast at a glance

- Homogeneous microstructure for improved machinability

- Re-sulphurized chemistry for optimal machinability

- Minimum levels of course carbides to improve the life of cutting tools

- Reduced carbon for improved weldability

- Lower carbon and higher chrome content for improved corrosion resistance

Swiss Steel Group offers a complete stainless tool steel solution with Corroplast mold base material, Formadur 2083 Superclean and Formadur PH X Superclean insert materials.

Contact:

John Stocker | Director of Sales

Phone: 800-323-1233

ext. 2345

j.stocker(at)swisssteelgroup.com

Applications:

Automotive industry

Mechanical and plant engineering

Energy Industry

Aerospace

Medical technology

Food and packaging industry

Structural and civil engineering

Hydraulic elements

Chemical industry

Mining